The car is now back from its COBB Access Port speed density tune and is running great. I have both a nice idle when creeping in traffic at low RPM, as well as some super freaky fantastic pull at the top end. The car ended up putting down 390 WHP on the dyno with 91 octane. If you take the nasty average of a 13% AWD drivetrain loss it puts the car at pretty much 440 HP at the flywheel 🙂

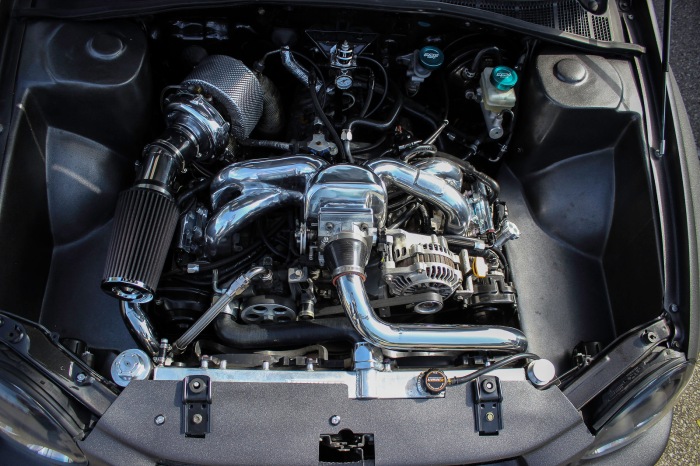

Since I had the car back I wanted to get my new intake installed that has the MAF sensor at the bottom which is now used as the intake temperature sensor for the speed density tune. I also picked up a new filter that fits the 3″ intake tube that also had a nice polished end.

With the new intake and the braided power steering lines, I wanted to fix up my existing engine bay panels to seal the hole that was used for the MAF wiring as well as create a section that would run the power steering lines underneath. Both panels were in pretty rough shape so I reinforced them with some new fiberglass cloth, applied some body filler, sanded and repainted them.

Below you can see the finished product that I am very happy with 🙂

Here are some better shots of the nice fixed up flat panels: